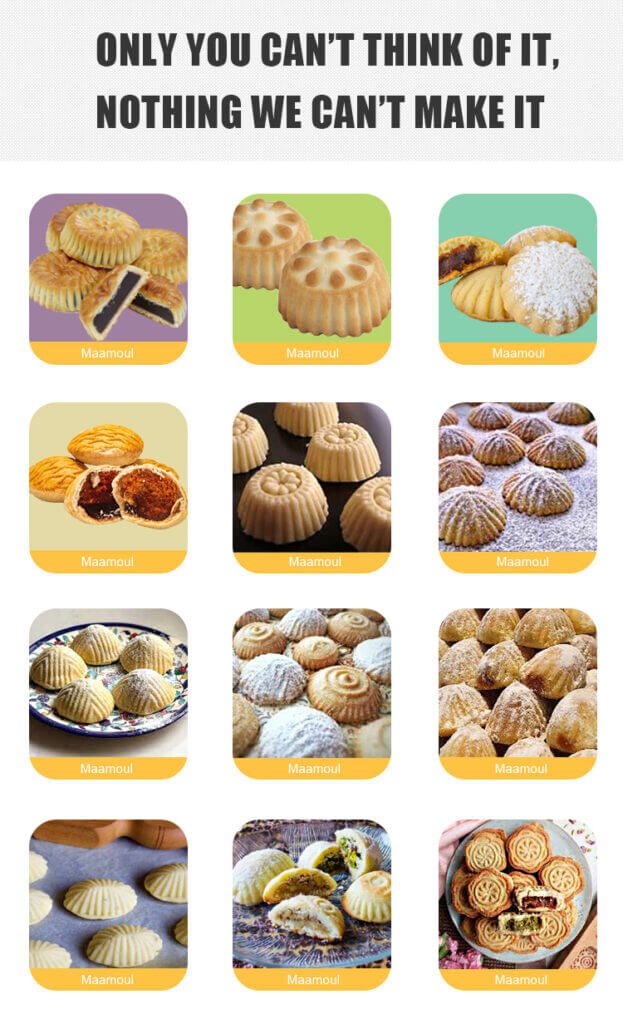

SY-800 automatic maamoul making machine is more suitable for factory use.It can make various kinds products by changing mould/shutter.304 stainless steel for machine body and food grade material to ensure safety and healthy.

For food manufacturers aiming to increase efficiency, consistency, and output, an automated maamoul production line solutions is a smart investment. From dough preparation to final packaging, a fully integrated system can streamline your entire production process, reduce labor dependency, and ensure product quality.

SY-800 Fully Automatic Customized Maamoul Forming Line-5 line Video

An automated maamoul production line integrates multiple machines to streamline the entire process—from dough preparation to final packaging. Each component plays a specific role and works in coordination with others to ensure continuous, efficient, and hygienic production.

This machine blends flour, water, oil, and other ingredients into a uniform dough. A spiral or planetary mixer is typically used for achieving consistent dough texture.

It handles various fillings such as dates, nuts, or sweet pastes. The filling machine ensures a consistent stuffing ratio for each maamoul piece, supporting multiple flavors and textures.

This is the heart of the line. It forms and shapes each maamoul piece with precise weight and structure, using interchangeable molds for different sizes or designs. It synchronizes filling and dough processes into a seamless output.

An industrial tunnel oven or rotary oven bakes the maamoul evenly. Temperature and time can be adjusted based on the product size and filling type.

After baking, maamoul pieces are transferred to a cooling conveyor belt to reach room temperature. Proper cooling prevents moisture buildup and maintains product texture.

The final step involves packing the cooled maamoul. Flow pack or pillow pack machines are commonly used to ensure hygienic sealing, extended shelf life, and a professional finish.

| Machine Component | Function | Automation Level | Optional Features |

|---|---|---|---|

| Dough Mixer | Prepares base dough | Semi/Full Automatic | Timer control, stainless steel body |

| Filling Machine | Dispenses stuffing into dough | Fully Automatic | Multi-filling support |

| Forming Machine | Shapes and forms each maamoul | Fully Automatic | Custom mold design, touch screen control |

| Baking Oven | Bakes the formed maamoul | Fully Automatic | Tunnel or rotary types |

| Cooling Conveyor | Reduces product temperature post-baking | Fully Automatic | Adjustable speed, food-grade belt |

| Packaging Machine | Packs finished products into retail packs | Fully Automatic | Date printer, nitrogen filling |

This integrated system is designed to maximize output while maintaining consistent product quality. Each unit communicates seamlessly to avoid delays, reduce manual labor, and ensure hygiene compliance across the entire line.

Seny Machine is a trusted name in the food machinery industry, with years of experience providing high-performance maamoul production solutions to clients around the world. Here’s what sets us apart:

We don’t just sell individual machines—we design complete, integrated production lines tailored to your factory’s needs, from dough mixing to final packaging.

Our team of engineers and technicians specializes in maamoul machinery development. With strong export experience, we understand international standards and offer reliable shipping, installation, and training.

We offer sample testing for product validation before purchase. After delivery, our global support network ensures smooth setup and operation with remote or on-site assistance.

Seny machines offer excellent value. Built with durable materials and advanced control systems, they are used in food factories across Asia, the Middle East, Europe, and the Americas.

Investing in an automated maamoul production line is a smart step toward boosting efficiency, improving product consistency, and reducing labor costs. At Seny Machine, we specialize in delivering fully customized maamoul production solutions tailored to your business scale and product goals.

With advanced technology, strong export experience, and reliable after-sales support, we help food manufacturers around the world succeed in a competitive market.

Ready to take your maamoul production to the next level?

Contact Seny Machine today for a free consultation or visit our website to explore the best solution for your factory.