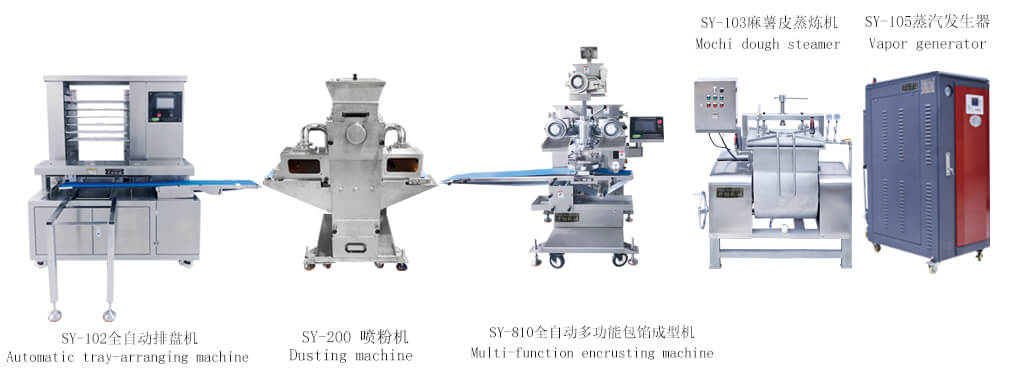

Seny has launched “Mochi Production Solutions” to provide comprehensive consulting services to meet your needs for automated mochi production, such as equipment procurement, plant layout planning, etc. Seny offers machines for everything from raw material processing to mochi molding and packaging.

In today’s competitive food industry, efficiency and product consistency are crucial for success. Seny Machine’s professional mochi production line machinery offers an advanced solution designed specifically for food manufacturers looking to streamline their mochi-making process. By automating key steps like dough mixing, filling, forming, and packaging, our equipment not only reduces labor costs but also ensures high-quality, uniform mochi products. Whether you operate a small-scale workshop or a large factory, our customizable machines adapt to your unique production needs, helping you increase output while maintaining strict food safety standards.

Mochi production line machinery offers significant benefits that directly impact the efficiency, quality, and cost-effectiveness of food manufacturing operations. By automating critical steps in the mochi-making process, these machines help food factories optimize production while ensuring consistent product standards.

1. Automation for Streamlined Production

The integration of automated processes—such as dough preparation, filling injection, shaping, and packaging—reduces manual labor requirements. This not only speeds up production but also minimizes human error, resulting in more reliable outputs.

2. Enhanced Efficiency and Throughput

Automated machinery can operate continuously at high speeds, enabling food factories to increase output without compromising quality. The precise control over production parameters ensures that every mochi piece meets preset specifications.

3. Consistent Product Quality

By standardizing the production process, mochi machines maintain uniformity in size, shape, and filling distribution. This consistency improves customer satisfaction and reduces waste due to defective products.

4. Cost Reduction

Reducing manual labor lowers operational costs, while minimizing production errors decreases material waste. The overall effect is a more economical manufacturing process.

| Advantage | Description | Impact |

|---|---|---|

| Automation | Reduces manual labor and human error | Faster, more reliable production |

| Increased Efficiency | High-speed continuous operation | Higher output capacity |

| Product Consistency | Uniform size, shape, and filling distribution | Improved quality and customer satisfaction |

| Cost Savings | Less labor and material waste | Lower overall production costs |

Implementing a professional mochi production line is a smart investment for food manufacturers aiming to scale their operations while maintaining the highest standards of product quality and operational efficiency.

Seny’s Automatic Encrusting and Forming Machine provides an innovative and efficient way to produce mochi. Simply load the steamed glutinous rice dough and your desired filling into the respective hoppers, and the machine will automatically mold and fill each mochi with accuracy. This process ensures every piece is soft and chewy, delivering a uniform and delicious filling throughout. The machine is versatile and works well with various fillings including peanut powder, sesame paste, red bean paste, jams, and even mochi ice cream, allowing manufacturers to easily adapt to market demands and consumer tastes.

The outer layer of mochi ice cream is the most significant production challenge, as the glutinous rice dough can easily crack or clump if the temperature and moisture content are not properly controlled. Aziguchi provides professional mochi ice cream premix powder to ensure that mochi ice cream will remain al dente after freezing. This commercial premixed powder requires only extra sugar and butter to form the dough; Many manufacturers prefer it because it saves time in weighing and heating various ingredients while reducing inconsistencies.

The SY-810 automatic stuffing machine can make 4000 mochi ice cream per hour. The unique filling system integrates toppings such as tapioca pearls, jam, and chocolate chips into the ice cream fillings to create popular and unique flavors. These include modern flavors such as Boba milk tea, Stracciatella, mint chocolate and fresh fruit. Other best-selling classic flavors include pistachio, chocolate, strawberry, mango, matcha, vanilla, Ube, coconut and latte. The SENY machine can also create two-tone mochi skins to create product differentiation and brand recognition for manufacturers and business owners.

Investing in Seny Machine’s professional mochi production line machinery is the key to elevating your food factory’s productivity and product quality. Our reliable, customizable equipment is designed to meet the unique needs of modern food manufacturers, ensuring smooth operations and consistent output. Don’t miss the opportunity to streamline your mochi production process, reduce labor costs, and respond quickly to market demands. Visit Seny Machine’s website today to discover how our advanced mochi production solutions can transform your business and help you stay ahead in the competitive food industry.