The High-Efficiency Cinnamon Roll Bread Production Line from Seny Machine is a fully automated solution designed for factories. It ensures consistent dough mixing, precise shaping, even baking, and efficient cooling, delivering high-quality cinnamon rolls with reduced labor and increased productivity.

In today’s competitive bakery market, producing consistent, high-quality cinnamon rolls quickly and efficiently is essential. Manual production often leads to uneven results, high labor costs, and limited output. A high-efficiency Cinnamon Roll Bread Production Line can solve these problems by automating key processes such as mixing, shaping, and baking. This not only ensures consistent taste and appearance but also significantly boosts productivity, making it the ideal solution for bakeries aiming to scale their operations.

Cinnamon Roll Bread Production Line Work Video

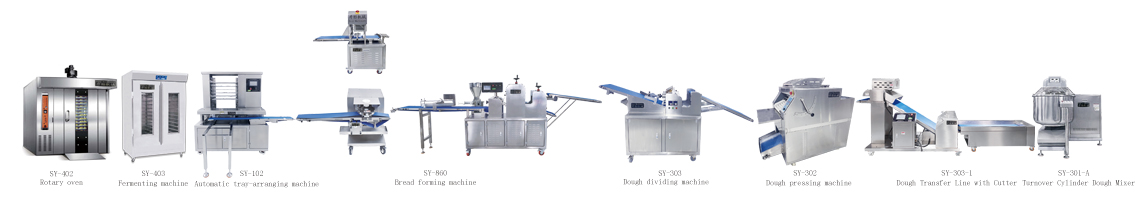

The Cinnamon Roll Bread Production Line is composed of several key machines that work together to ensure high efficiency and consistent product quality:

Dough Mixer – This machine ensures uniform mixing of flour, sugar, butter, and yeast, producing a smooth and elastic dough. Consistent dough quality is critical for the final texture and taste of the cinnamon rolls.

Dough Divider & Rounder – After mixing, the dough is divided into equal portions and rounded to ensure uniform size. This step guarantees consistent baking and presentation of each cinnamon roll.

Sheeter & Roller – The dough is flattened and rolled to the desired thickness, preparing it for filling and shaping. Precise thickness control ensures even baking and consistent texture.

Filling & Shaping Machine – This machine evenly applies cinnamon and sugar filling and shapes the dough into rolls. Automation here reduces manual labor and ensures every roll meets quality standards.

Proofer & Fermentation System – Controlled temperature and humidity allow the dough to rise optimally, creating soft and fluffy rolls. Proper fermentation ensures the desired texture and flavor.

Oven – The rolls are baked evenly at controlled temperatures to achieve a golden-brown crust and perfectly cooked interior.

Cooling Conveyor – After baking, rolls are cooled efficiently to preserve freshness and prevent condensation, preparing them for packaging.

Each piece of equipment works in harmony to streamline production, reduce labor costs, and maintain a consistent high-quality output for bakeries.

Choosing a high-efficiency Cinnamon Roll Bread Production Line comes with more than just advanced machinery—it requires reliable support to ensure smooth operation. Our services include:

Installation and Commissioning – Professional guidance during the setup process ensures that all equipment is correctly installed and fully operational.

Operator Training – Comprehensive training programs teach your staff how to operate the machines safely and efficiently, maximizing productivity.

Warranty Policy – Our machines come with a clear warranty covering manufacturing defects, giving you peace of mind.

Spare Parts Replacement – Easy access to essential spare parts ensures minimal downtime and uninterrupted production.

Remote Technical Support – Expert assistance is available remotely to troubleshoot issues, optimize performance, and answer any questions.

With these services, customers can confidently run their production lines, knowing that support is always available whenever needed.

Investing in a high-efficiency Cinnamon Roll Production Line is the key to increasing productivity, ensuring consistent product quality, and reducing labor costs. With advanced equipment, seamless automation, and reliable after-sales support from Seny Machine, bakeries can achieve professional results effortlessly.

Take your bakery to the next level—contact Seny Machine today to learn more about our production lines and get a customized solution for your business needs.